Niupai Machinery & Elecronics: Bring a variety of shedding devices and heald frame equipment to the exhibition

Oct 22, 2025 | by

Jiangsu Niupai Machinery & Elecronics Co, ltd. is National Specialized and New "Little Giant" Enterprise, National High & New Technological Enterprise, Jiangsu Provincial Research Center of Loom Shedding Engineering Technology and Jiangsu Provincial Enterprise Technology Center. The company has obtained SGS-certified ISO9001 quality management system, a globally recognized standard.

Niupai specializes in the R&D and manufacturing of cam shedding device, dobby shedding device, jacquard shedding device and heald frames for water-jet looms, air-jet looms as well as rapier looms.

Cam shedding device

NPW411 positive cam shedding device is primarily used for high-speed water-jet looms, offering the advantages of high rigidity and a stable structure. lt can achieve a maximum speed of 800 RPM (111/111*12 fabric pattern, 1900mm width).

NPW410 positive cam shedding device is primarily used for highspeed water-jet looms, offering the advantages of high rigidity and a stable structure. lt can achieve a maximum speed of 1000 RPM (4/1 fabric pattern, 1900mm width).

The NP4620B high-speed cam shedding device for air-jet looms is suitable for weaving fabrics that require up to 10 heald frames and no more than 6 weft picks. lt is characterized by high speed, high efficiency, and stable reliability.

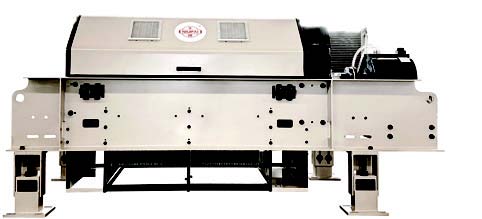

Electronic dobby device

NP5400D Electronic Dobby is top-mounted intelligent positive shedding device for water-jet looms. The lubrication oil is forced to circulate via oil pump, and oil level sensor is adopted to avoid lacking oil. lt is characterized by compact structure and easy operation. Thus, it is especially suitable for fast speed and wide unbalanced fabrics.

The low-positioned positive electronic dobby NP5600A is intelligent shedding device matching with air-jet looms. Multiple cam curves are provided for weaving different fabrics.

Electronic jacquard device

NP6016C is driven by a direct-drive motor. Compared to cardan shaft transmission, it offers a speed increase of over 30%, saves 400mm of longitudinal space on the loom, and has no exposed transmission components, making it safe, reliable, and low in failure rate and maintenance cost. The low vibration extends the lifespan of M5 modules and reduces noise. The independent drive can reduce the formation of stop marks on the fabric, lower the motor power consumption of the loom, and enable weaving of complex fabric varieties in combination with electronic dobby. Compared to servo motor (requiring a matching reducer), it offers a speed increase of over 10%, high work efficiency, high productivity, significantly reduced failure rate, near zero motor maintenance costs, approximately 5% space saving, and energy savings of about 5-15%.

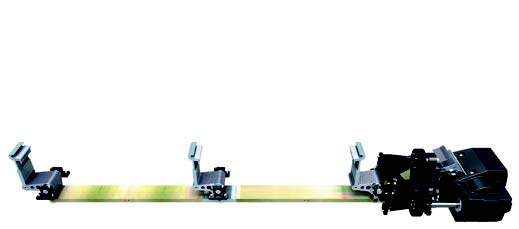

Heald frame

The aluminum alloy heald frame adopts high strength aluminium alloy extrudate, whose surface is processed with electrophoresis treatment, and the shape design has earned national patent.

The plastic parts adopt Dupont materials. The quality is reliable and guaranteed.