Rifa Textile Machinery:Shaping the future of textile manufacturing through innovation

Oct 22, 2025 | by

Founded in 1993, Zhejiang Rifa Textile Machinery Co., Ltd. is a national key high-tech enterprise, a leading enterprise in China’s machinery industry, a CIMS engineering demonstration enterprise under the 863 Program, a national CAD application engineering demonstration enterprise, a high-tech enterprise of the National Torch Plan, and a vice president unit of the China Textile Machinery Association. It currently runs three subsidiaries, namely, Shandong Rifa Textile Machinery Co., Ltd., Anhui Rifa Textile Machinery Co., Ltd. and Zhejiang Rifa Textile Machinery Tech Co., Ltd.

Guided by the vision of “becoming an agile international company”, the mission of “providing intelligent textile equipment system solutions to help users gradually realize the dream of a digital factory”, and the core values of “quality, innovation and rapid response”, Rifa Textile Machinery is devoted to advancing the “digital technology” in mechanical and electrical industry, and has become a well-known textile equipment manufacturer with excellent reputation at home and abroad.

Over the years, the company has successfully developed comprehensive solutions across spinning, fiber preparation, weaving and non-woven sectors. Its diverse product portfolio includes hundreds of machines, such as blow-room machine, draw frame, rotor spinning machine, air-jet vortex spinning machine, two-for-one twister machine, twisting machine for tire cord, false-twist texturing machine, precision winding machine, automatic warp drawing machine, air-jet loom, water-jet loom, rapier loom, terry loom, specialty loom, circular knitting machine, seamless knitting machine, hosiery machine and non-woven equipment. These products have been distributed across China and exported to over 30 countries and regions, maintaining a leading market share in each category.

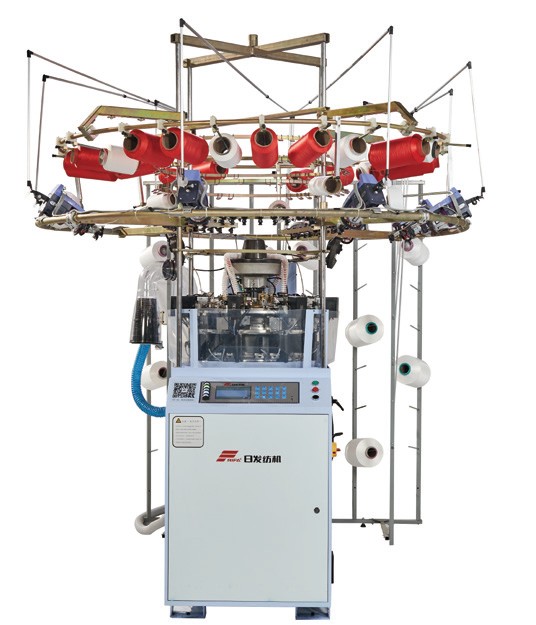

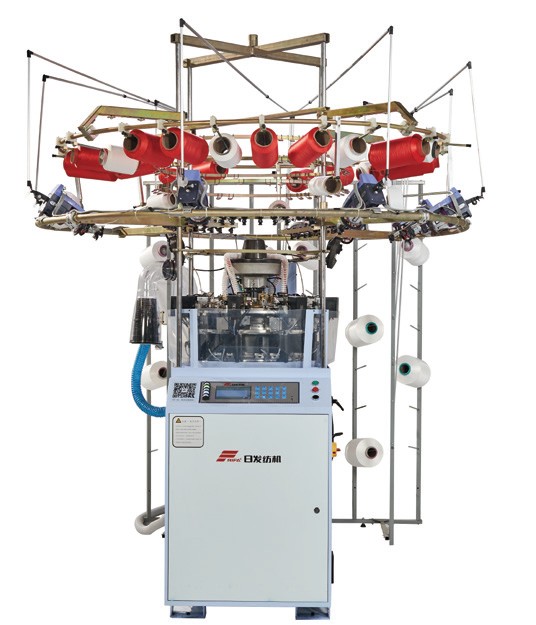

Automatic linking socks machine

Equipped with a stable stitch-by-stitch linking device, it’s a fully computerized single cylinder socks knitting machine that integrates knitting, linking and turning-out functions. It is capable of knitting new fashion socks, high-quality men’s and women’s cotton socks, athletic socks, selected terry socks, invisible socks and stockings, etc. Compared with conventional socks production, all-in-one socks knitting machine has the following advantages:

•Simplified production process, synchronous knitting and linking, and enhanced production efficiency.

•Cost savings in raw materials due to less waste yarn; no need to invest in linking machine thanks to the built-in linking process; labor cost savings due to less operators.

•The truly high-quality stitch-by-stitch linking technology guarantees socks finishing, delivering greater comfort and durability.

Seamless machine

Rifa Textile Machinery remains committed to the research of value-added knitting technology, aiming to help customers produce better products in a more economical way. The RFSM seamless underwear machine is a result of this effort. The underwear machine can use natural fiber, synthetic fiber, artificial fiber, spandex and covering yarn as raw materials, and serves as special processing equipment for onetime knitting and production.

Rifa Textile Machinery is devoting itself to creating a brand new theory of digital technology, establishing an interactive platform of “human flow, material flow and information flow”, and harmonizing technology, environment and manufacturing, with the goal of becoming a manufacturing base characterized by “informatization, agility and internationalization”.