Chen Hailin, Huashing Textile Group: Weaving a brighter future with technology

Aug 22, 2025 | by Zhong Mengxia

Within the Huasheng Textile Industrial Park in Wudi Economic Development Zone, Binzhou, Shandong, a impressive figure over 1.8 meters tall shuttles back and forth between home and production workshop. Chen Hailin, Chairman of Shandong Huasheng Textile Group Co., Ltd. and leader of Hong Kong Huasheng Group, has the boots-on-the-ground confidence when discussing technological breakthroughs. With over three decades in the textile industry, this "technology obsessive" acts as a "boundary-breaker," infusing the sector with the new DNA of green, intelligent manufacturing through knowledge and innovation. Huasheng Textile’s core values - Be realistic, efficient, outstanding, pioneering and innovative. And create value together - is actually Chen's working principles.

Breaking barriers: A leader armed with knowledge

"The cocoon of conventional thinking need to be opened with the blade of knowledge." This reflects Chen’s personal discipline and a strict requirement for his management team. Deeply aware of knowledge's power, Chen is constantly reading, drawing wisdom from books. He actively recommended the company management staffs to read classic books, and he firmly believed that the breakthrough of textile industry not only needed technical equipment, but also needed to break previous old thinking.

This reverence for knowledge prevents him from being a conventional "boss." To employees, he's the Chief R&D Expert: He can engrossed himself in technical processes for hours, and discussed passionately with other researchers from dawn till dusk. "Rules exist to be broken," he states, leaving no room for compromise. This relentless drive to expand cognitive boundaries led his team beyond the confines of manufacturing towards self-driven, technology-powered innovation. He has built an efficient, professional operational team featuring departments like the National Ultrasonic Dyeing & Finishing Engineering Research Center, Engineering, Production, Quality Control, and HR. This robust framework, supported by over 30 specialized managers, ensures smooth, high-performance operations, embodying his commitment to "Efficient and Outstanding."

Forging technological frontiers: Revolutionary in ultrasound dyeing

"This technology will rewrite the DNA of the dyeing industry." Standing before the chalkboard, Chen sketches the intricate workings of ultrasonic dyeing for journalists. He explains how ultrasound replaces traditional dyeing, drastically reducing wastewater. This technology is a "breakthrough work" promoted by his persistent efforts for many years, and it also practices the entrepreneurial spirit of Huasheng Textile Innovation.

As a tech-driven leader, Chen's dedication to innovation borders on obsession. He directs 15% of annual revenue into R&D. Under his guidance, Huasheng transformed from a original equipment manufacturer (OEM) into an industry model, holding 37 patents (including 14 invention patents, 2 of them high-value). The pioneering ultrasonic dyeing process revolutionizes the entire "dissolve-adsorb-dye" cycle: Where traditionally dyeing 1 ton of cotton fabric took 10-14 hours and 120-150 tons of water, Huasheng's disruptive open-width processing technology shorten time to just 6 hours (with only 2.5-3.5 hours in the dyeing vats) and water usage to 40-50 tons. This slashes processing time by two-thirds, reduces overall costs by two-thirds, achieves a color fastness of 4 or higher, saves 50% water, and generates minimal wastewater, perfectly meeting stringent international ecological standards like GOTS and OCS. Even brands like Armani praise the colorfastness and functionality of Huasheng fabrics, showing the market impact of their technological breakthroughs.

According to China Dyeing and Printing Association data (2024), China's output of dyed and printed fabrics by major enterprises reached 57.201 billion meters. Knitted fabric dyeing and finishing output was equivalent to 10.296 million tons. With ultrasonic technology penetration estimated at about 1%, national ultrasonic-process knitted fabric output was approximately 103,000 tons. In 2024, Huasheng produced 27,200 tons, accounting for 26.41% market share in this segment. The Shandong Textile and Apparel Association confirms Huasheng as the provincial leader in its niche market for three consecutive years.

Huasheng invested 60 million RMB setting up a R&D center collaborates with Sichuan University, Donghua University, Chengdu Textile College. Beyond recruiting top talents from Shandong Province, the company has built a dedicated R&D team over 100 people, fully integrating ultrasonic technology into the dyeing and finishing process. The "National Ultrasonic Dyeing & Finishing Engineering Technology R&D Center," spearheaded by Huasheng, is recognized by the China Textile Engineering Society as an industry benchmark, driving green, low-carbon development.

"In the production process, anything that can improve efficiency is our research direction." This directive from Chen guides the R&D team, enabling Huasheng to master world-leading technologies like open-width pre-treatment and COPY dyeing processes, significantly lowering pollution and waste rate.

Expanding the industry: From tech breakthrough to ecosystem building

"Textile is an ancient industry, but those clinging to the past will be forgot by the times." Chen Hailin's vision extends far beyond a single technology. He drove the 2 billion RMB project of Shandong Huasheng Textile Technology Industrial Park in Binzhou. 414 acres, 180,000 sqm of modern factories, 30,000 sqm of talent apartments and R&D buildings, and a wastewater treatment plant handling 15,000 cubic meters daily. The group is going forward to a fully integrated R&D, weaving, dyeing and finishing, and garment manufacturing hub, which realize its envision of "one industrial park equals one complete supply chain", refecting the group’s motto “Creating Shared Value”.

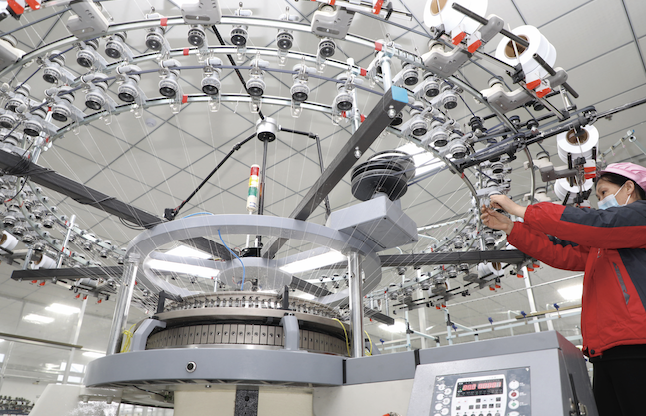

This is not a accident. As Chairman of Hong Kong Huasheng Group, Chen established the Shandong Wudi base. Acting as an "anchor enterprise," he built a "2+1+2" industrial ecosystem: empowering two upstream weaving factories, one dyeing and finishing center, and two downstream garment factories. This fosters an industrial cluster with annual output exceeding 10 billion RMB. Currently, it forms a smart chain of over 300 dyeing vats and 13 production lines. Also, there is a dedicated polyester line being installed. A 30,000 sqm garment workshop is set to launch soon. In the future, the daily output is expected to reach 300 tons, generating 2.5 billion RMB in annual output value, 170 million RMB in tax revenue, and providing over 2,000 jobs.

Today, Huasheng's smart factory integrates digital management systems with energy cascade use and water recycling, reducing energy consumption per unit of output by 30% below the industry average. It has earned praises from Shandong government. From "Specialized, Refined, Differential and Innovation" (SRDI) enterprise to "Gazella Company " and "Unicorn Company," from Shandong's New/Old Energy Conversion Key Project to intelligent green transformation awards, these honors reflect Chen's dual-driven strategy of "Intelligence and Green" and perfectly embody the company's values: "Integrity, Quality, Green Manufacturing, Technology-Driven Dyeing."

Be true to the goal: Infusing vitality into textile industry

"Huasheng signifies 'Prosperous China'." Chen Hailin said. From Huasheng Group's founding in 2018, the establishment of Shandong Huasheng Innovation Textile Technology in 2019, to becoming a core supplier for global giants like UNIQLO, Skechers, and Adidas, the company generated over 900 million RMB in revenue over the past three years. Chen remains the belief that "Science and technology are the primary productive forces", and take “Intelligent Development, High-end Talent, Global Market , International Branding” as his strategic goals. Chen’s relentless efforts in the past few decades prove that the vitality of traditional industry lies in innovation.

Chen Hailin is a "boundary-breaker" in the industry. He uses knowledge to expand the limits of traditional thinking, deploys technology to break down industry barriers, and builds ecosystems to reshape the future of manufacturing. We can see that he is steadfastly guiding the enterprise along the path of "being realistic, efficient, outstanding, pioneering, and innovative while creating value together."