Man-made Fibers: Quantity reduction & quality improvement

Jan 15, 2016 | by

Man-made Fibers: Quantity reduction & quality improvement

- Interview with Duan Xiaoping, President of China Chemical Fibers Association

Original by Niu Fang, Translated by Zhao Zihan

Man-made fibers, as a huge part in the downstream of textile industrial chain, are shouldering the heavy responsibility of raw material supply of the entire industry. During the 12th Five-Year Program period, China’s man-made fiber industry suffered pressures from industrial structure adjustment and continued downward operation while completing its industrial mission. The enterprises generally felt tired to live; nevertheless, without any weakening of confidence in the future of the industry.

On the occasion of the end of the 12th Five-Year Program, the reporter of China Textile had an interview with Duan Xiaoping, President of China Chemical Fibers Association, for an in-depth understanding of man-made fibers’ current status, future development space, industry development environment changes as well as some of the hidden phenomena and trends that the industry has revealed.

Duan Xiaoping, President of China Chemical Fibers Association

China Textile: Could you please summarize the major achievements of China’s man-made fibers industry during the 12th Five-Year Program period?

Duan Xiaoping: I’d like to use three sentences to summarize the major achievements of China’s chemical fiber industry during the 12th Five-Year Program period. The first is that a worldwide leading position has been gradually established in the field of conventional fiber production. The second is that high performance fiber production has been on the upgrade everywhere, significantly reducing the gap with the developed countries for nearly 30 years. The third is that the industrial chain collaboration and brand building enjoy popular support, seeing initial results.

○ Interpretation:

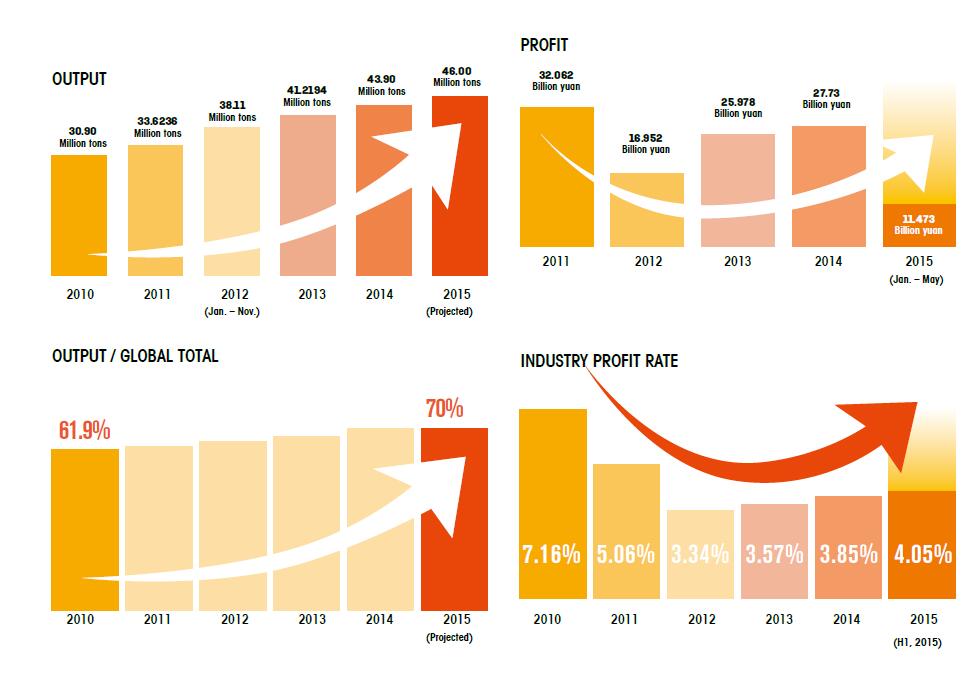

China is currently the largest producer and consumer of man-made fibers in the world. In terms of industry scale, China’s man-made fiber output was 43.9 million tons in 2014, accounting for 69.4% of global chemical fiber production, among of which, however, the unconventional varieties of high-performance fibers and of bio-based fibers were respectively less than 100,000 tons, and the rest more than 43 million tons were all conventional varieties as well as their differentiated products.

Imports: in the past five years, China chemical fiber imports always remained at 800,000 to 900,000 tons / year. In terms of the ratio of import volume to domestic production scale, the largest proportion went to acrylic followed by nylon filament, viscose staple fiber, spandex, and viscose filament.

Therefore, the industry scale and import data are strong proof of Mr. Duan’s first sentence, a more clear understanding of the current global status of China’s chemical fiber production in the field of conventional fiber.

10 years ago, high-performance fibers industrial production in China was almost a blank. During the past 10 years, high-performance fibers have been developed from scratch in China, and today have included almost all varieties of carbon fiber, aramid, ultra high molecular weight polyethylene, polyphenylene sulfide fibers, basalt fibers, and polyimide fiber, among which some species are enjoying more than half of world total production. Especially during the 12th Five-Year Program period, high-performance fibers industry has made sustained efforts in the construction of the whole industrial chain, in the aspects of stabilizing production technology, expanding applied technology, equipment research and development, and development of downstream products, witnessing significant progresses.

During the 12th Five-Year Program period, the “China Fibers Fashion Trends” event jointly organized by Consumer Products Division of Ministry of Industry and Information Technology of the People’s Republic of China, China Chemical Fibers Association, Donghua University, and National Textile Chemical Fiber Product Development Center has held for four consecutive sessions. The event led the upgrading of Chinese textile industrial chain oriented to the development of new products as well as demand-driven innovation, enhancing the overall competitiveness of the industrial chain and improving the contribution rate of fiber brands to textile chemical fiber industry.

Chemical fiber industry saw an average profit margin of 3.85% in 2014; while that of the fiber varieties selected into China Fibers Fashion Trends was 18.71%, greatly boosting the enthusiasm of companies to develop new products, and promoting the brand-building work of the industry.

China Textile: China’s chemical fiber output will have reached 46 million tons by the end of the 12th Five-Year Program. It has been already an extremely large figure, which has given rise to a number of discussions around China’s chemical fiber production capacity. Could you please make an analysis of the total capacity issues in the future development of the industry? How about the development space in the future?

Duan Xiaoping: In the past twenty years, the global textile fiber processing volume maintained a 3.02% annual growth rate, and China’s growth rate was far higher than the global. With global economic growth and per capita fiber consumption increases, global fiber processing volume is still expected to see further growth at an average annual growth rate of 2.8% to 3.0%. The most will come from man-made fibers and China’s growth rate will still remain above the global average, but China’s growth rate will present a substantial decline owing to the original base number, together with the restructuring of the global division of labor and the moderation of Chinese economy.

In the current 13th Five-Year Program, the goals of total amount is described as: by 2020, chemical fiber production will have reached 55 million tons, with an average annual growth rate adjustment from former 9.2% to 3.6%.

China Textile: During the 12th Five-Year Program period, China’s economic development environment has undergone tremendous changes. Could you please analyze the development environment changes of chemical fiber industry in that period as well as the impacts to the development of enterprises?

Duan Xiaoping: The current Chinese economy has entered the new normal when various impacts to the development of the industry have changed, including consumer demand, investment demand, exports and balance of payments, production capacity and industrial organization, the factors of production, market competition, resource and environmental constraints, financial risk accumulation and resolving, and resource allocation model and macro-control methods. Tertiary industry’s contribution to the GDP showed a rapid increase while the contribution of capital-intensive industries to the industrial economic growth is gradually being reduced. The carrying capacity of resources and the environment is in a downward trend. Global industrial revolution has raised the curtain.

The Belt and Road Initiative is contributing to global chemical fiber industry division adjustment. Recently, economists also put forward “supply-front reforms”, proposing new guidelines to the development of the industry. And China’s chemical fiber industry has also entered the “new normal” development when the competition between enterprises has been gradually developed into such soft power as resources, channel, brand and standards, bidding farewell to the past competition in equipment, scale, yield, and cost. Enterprises are required to speed up the adjustment of product structure and technological innovation, capacity increase control, inventory optimization, and application development in order to develop new products to meet market demand relying on technological innovation.

China Textile: On the occasion of the end of the 12th Five-Year Program, which important phenomenon and trends appeared in the development of the industry? What kind of certain direction does it indicate?

Duan Xiaoping: A big differentiation in the development of the industry emerged from last year and is gradually becoming obvious. Some SMEs who are doing a good job in product development are enjoying profitability as that in 2011. What behind this phenomenon reveals a trend of the future development of the industry, i.e. those enterprises focusing on product development and differentiation will be given priority in entering a healthy development.

In addition, large-scale enterprises in the industry have also accelerated the pace of extending to the petrochemical industry. For example, Shenghong and Hengyi are beginning the layout of more front-end of the industrial chain. Future chemical fiber industry should, by vertical integration and horizontal integration, encourage large-scale, strong, and complete set of integrated enterprises of PTA, polyester business, caprolactam, and nylon to be engaged in refining industry, achieving integrated production of oil refining, chemical industry, and chemical fibers. It is expected that by 2020 there will have been three to five enterprises who can achieve integrated sales revenue of more than 150 billion yuan, further enhancing the industrial concentration and overall competitiveness.

Big Data

Constant optimization of industrial structure

-

Industrial concentration was further improved. Enterprises with a production scale of above 200,000 tons / year reached 57, an increase of 24 over 2010, accounting for 66.5% of production capacity of the industry.

-

Technical structure was advanced to a higher level. Differential rate amounted to 56%, 10 percentage points higher than that in 2010. Among the three major application fields, the industrial proportion was 28%, 5 percentage points higher than that in 2010.

-

Direct material self-sufficiency rate saw somewhat increase. PTA and other major chemical fiber raw material self-sufficiency rate grew from 77% in 2010 to 97%, while caprolactam self-sufficiency rate dramatically increased from 43.7% in 2010 to 87.3%.

-

High-performance fiber production variety coverage was the most extensive worldwide and many products made important progress in industrialization.

-

Bio-based fiber new technology development and industrialization saw significant progress.

Remarkable success in R & D and technological progress

-

R & D: New product R & D expenditures in the above-designated enterprises accounted for 1.3% of the main business revenue; sales of new products in the main business revenue reached 20.7%. Among the whole industry, there were 12 state-level and 45 provincial-level enterprise technical centers. The key core technology achievements won 6 National Prizes for Progress in Science and Technology and 13 First Prizes for Progress in Science and Technology in Textile Industry.

-

Technological progress: Production technology and equipment for respective 100,000 tons / year caprolactam and 2.5 million tons / year in one production line achieved manufacturing domestically. Production technology for new varieties was significantly improved, accompanied by continuously improved product quality and added value. Superfine denier filament (dpf <0.5) melt direct spinning enjoyed a leading international large-scale production technology; polyester industrial yarn achieved melt direct spinning, filling the international blank in chemical fiber technology; differential functional fibers saw a growing mature scale production and application.

Growing brand development

-

China Chemical Fibers Association’s four consecutive releases of “China Fibers Fashion Trends” promoted the publication and application of new chemical fiber products, and gradually formed a new model for the effective contact between the upstream and downstream of chemical fiber industrial chain.

Effective promotion of the standardization work

-

Totally, 9 national standards, 104 industry standards and 23 association standards were enacted and revised, and the number of chemical fibers exceeded the combined total in the history. China Chemical Fibers Association was awarded one of the National Standard System Reform Pilot Units.

Significant achievements in energy-saving and emission-reduction

-

More than 40 key technologies were promoted in energy-saving and emission-reduction; 16 carbon footprint product certification and 10 regeneration system certification were completed by the corporates of the industry. “Viscose Fiber Access Conditions” “regeneration chemical fiber (PET) industry standard conditions” and other documents were released.

(The above figures are referred to the end of 2014)