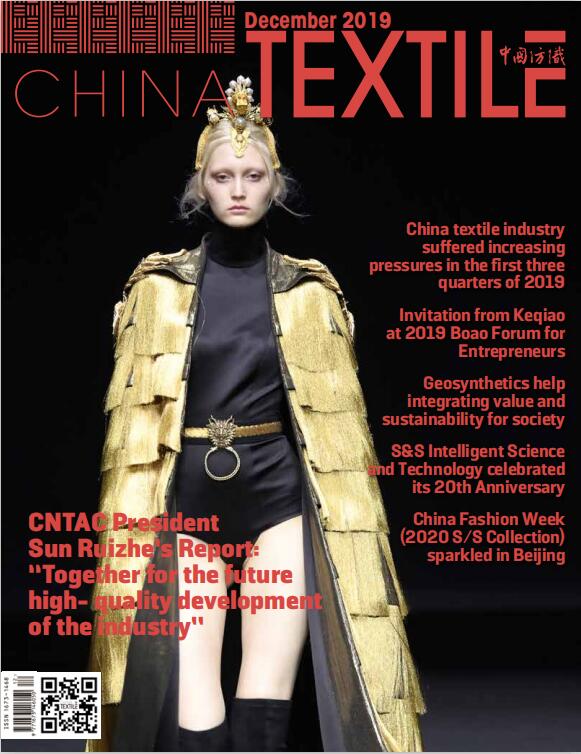

Together for the future high-quality development of the industry

Report by by Sun Ruizhe, President of China National Textile and Apparel Council

Dec 12, 2019 | by CT

Editor’s note:

On December 5th, 2019, four conferences including the Sixth Session of the Fourth Executive Council Enlargement Meeting of China National Textile and Apparel Council, 2019 China Textile Innovation Conference, 2019 National Textile Industry Cluster Review Conference, and the Eighth National conference on Promotion of Management Innovation Achievements in Textile Industry were held in Beijing. During the conference, Mr. Sun Ruizhe, President of China National Textile and Apparel Council, made a work report entitled “Together for the future high-quality development of the industry”. The report is divided into four parts: The goal of building a textile power in China has been basically completed; The main work carried out by CNTAC in 2019; The new situation and fresh changes in the current industry development; The main work to be done in the next stage by CNTAC.

Part 1 The goal of building a textile power in China has been basically completed

The performance achieved in building a textile power

China National Textile and Apparel Council (CNTAC) issued the “Outline of Building a Textile Power (2011 - 2020)” (hereinafter referred to as the “Outline”) in 2012 to meet the development needs of building a well-off society in an all-round way. Since the establishment of the goal of a textile power, facing the complex and changing external environment and the new normal in economic development, Chinese textile industry has closely focused on the decisions and plans made by the Party Central Committee as well as the the overall layout of the Five-Sphere Integrated Plan, so as to pursue innovative, coordinated, green, open and shared development with supply-side structural reform as a focus and high-quality development as the direction. It has opened up a new prospect for the development of the industry.

China’s textile industry has formed the world’s largest and most complete industrial system. In 2018, China textile industry’s total fiber processing accounted for more than half of the world’s total; textile and apparel exports accounted for more than one-third of the world’s total. China textile industry has successfully covered all the world and has made important contributions to the construction of a community with shared future for mankind. The status of the textile industry as a pillar industry of the national economy and an important livelihood industry is even more prominent.

According to the Fourth National Economic Census, as of the end of 2018, the number of corporate entities, total assets, and total operating income of the textile and apparel industry accounted for 9.5%, 4.8%, and 5.4% of all industries, respectively. The number of employee was 11.032 million, accounting for 9.6% of the national industries, which reached 16.12 million plus the people working in wholesale and retail. The proportion of textile and apparel exports in the country’s total exports of goods was 12%; the net foreign exchange earnings of textiles and garments were 250.19 billion USD, accounting for 71.1% of the national trade surplus.

Specifically:

There is a new leap in scientific and technological innovation, which has shifted from “following others” to a harmonious status featured by “following, synchronizing, and leading”. Industry R&D investment and innovation output have increased significantly. In 2018, the R&D investment intensity of textile enterprises above designated size was 0.9%, which was twice the level in 2011. Among them, the chemical fiber industry reached 1.34%, 0.46 percentage points higher than in 2011. The total number of effective invention patents in textile, garments and chemical fibers was 18,854, which was 5.6 times that of 2011; the per capita operating income of textile enterprises above designated size was 758,000 yuan / person, a 46% increase compared with that of 2011. The industry has made major breakthroughs in many fields.

In terms of materials, conventional fibers have taken the lead in the world, while high-performance and highly functional fibers have achieved a change from quantity to quality. Among them, carbon fiber in the civilian field has significant advantages. High-performance fibers such as high-strength high-modulus polyethylene and meta-aramid have achieved large-scale production and reached international advanced levels. Industrial textiles accounted for 28% of total fiber processing, widely used in aerospace, infrastructure and other fields.

In terms of equipment, the level of intelligence, service and greening of textile equipment has been greatly improved, and the overall level and manufacturing capacity are among the highest in the world.

At present, China’s textile machinery product sales account for about 50% of the world’s total; China’s textile machinery’s domestic market share has reached 80%; the localization rate of key parts and components of the high-end equipment amounts to over 50%; complete digital cotton spinning equipment has also achieved industrial application, and less than 20 people is required for 10,000-spindle spinning. The textile industry has become one of the few industrial sectors in China with closed-loop innovation capabilities throughout the industrial chain. The systematic innovation advantage makes China’s textile industry increasingly become an important source of global textile technology innovation.

Brand building has reached new heights. The industry’s brand awareness, design ability, and creativity have been greatly improved, while leapfrog development has been achieved in terms of quantity, quality, and content. The brand system of manufacturing brands, consumer brands and regional brands is taking shape. Since 2012, “China Fibers Fashion Trends” has released about 150 fiber brands, and “Fabrics China” sees more than 800 shortlisted companies each year.

The Ministry of Industry and Information Technology has announced 46 textile and apparel creative design pilot demonstration parks (platforms), which have incubated a large number of textile and apparel brands. Outstanding consumer brands such as Anta, Li Ning, Bosideng, Aimer, and Peacebird have begun to come onto the international stage, and a large number of Chinese designer brands have emerged. A variety of outstanding manufacturing companies such as Shenzhou, Shenghong, Hengli, Hengyi, Weiqiao, Ruyi, Luthai, Chenfeng, Sunvim, Loftex, Yueyue, and Hongliu have become industry models for global manufacturing brands. Regional brands are developing rapidly. Keqiao, Dalang, Humen, Puyuan, Shengze, Changshu, Xiqiao, Dieshiqiao, Xingcheng, Binzhou, Jimo, Shishi, Zhili, Xucun, etc. have become popular landmarks and become new business cards for regional development.

The 10 “regional brand pilot zones” identified by CNTAC cover 10,685 companies, and the R&D investment intensity exceeds 1%; 20.2% of the companies have established a brand cultivation management system, and 30.7% have participated in brand professional training; social responsibility construction has been carried out in 9 regions, while 18.6% enterprises in 3 regions have established social responsibility management systems.

Textile intangible cultural heritage has achieved creative transformation and innovative development in the industry. The international influence and radiation of platforms such as Intertextile Shanghai Apparel Fabrics, Intertextile Shanghai Home Textiles, CHIC, and China Fashion Week have been significantly enhanced. The rapid development of industry brand construction has played an increasingly important role in building cultural confidence and improving China’s fashion discourse power.

Sustainable development has entered a new phase. Social responsibility has become the consensus of industry development. Sustainable development practices are accelerating, and the market for responsible consumption has taken shape. From the supply of raw materials, design and R&D to processing and manufacturing, the entire manufacturing system is accelerating its transformation towards an ecological and green direction. An industrial system for recycling, sorting and reusing waste textiles is taking shape. Since 2016, in the construction of the green manufacturing system carried out by the Ministry of Industry and Information Technology, among the textile industry, 89 types of green products, 69 green factories, and 4 green supply chains have been selected.

As the industry continues to adjust its industrial structure and eliminate outdated production capacity, the total amount of pollutant emissions has decreased significantly. Since the “Twelfth Five-Year Program” period, the water consumption per unit product in the dyeing and printing industry has decreased by 36%, the comprehensive energy consumption per unit product has decreased by 40%, the water reuse rate has reached 40%, and the backward production capacity has been eliminated by 11.6 billion meters.

Technological innovation has reached new heights. Advanced technologies such as energy conservation & emission reduction, and resource recycling have enjoyed rapid promotion and application in the industry. A series of key technologies for clean production, such as low-temperature rapid pretreatment, cold-pad-batch dyeing, and non-aqueous dyeing, have achieved breakthroughs and industrialized production. Since 2016, a total of 24 green manufacturing groups and industry standards have been formulated and revised; the products of 27 chemical fiber companies have passed the “green fiber” logo certification. Sustainable practice has laid a solid foundation for the sustainable development of the industry, and the industry is playing an increasingly important role in building a beautiful China.

Talent construction is characterized by fresh highlights. The supporting factors for the development of the industry have begun to change from the quantity of labor to the quality. Positive progress has been made in the construction of industry talent teams. The education system has been improved, and the training model that pays equal attention to higher education and vocational education with Industry-University-Research collaboration has been put in place.

From top-level design to specific measures, from content coverage to crowd coverage, from teacher team building to student training methods, they are all more systematic; the pace of international cooperation of talents is constantly accelerating, and the scale of two-way study abroad is continuously expanding; teaching tools, teaching management, and teaching content is speeding the digitized transformation.

The talent team is more reasonable, and a textile industry talent team of moderate size, reasonable structure, excellent quality, and vitality has initially formed. The supply of high-level talents in the industry has improved. In 2018, the R&D personnel of textile enterprises above designated size (excluding textile machinery) was 133,000 full-time equivalent, an increase of 61.3% over 2011. A number of outstanding entrepreneurs, scientists, designers, and skilled personnel with the spirit of the times, international perspectives, and professional capabilities have emerged in the industry, playing an important role in demonstration and leadership in the industry.

On the whole, most indicators of China’s textile industry have reached or even led the world’s advanced level. The goal of the textile power planned by the “Outline” has basically been achieved. China’s textile industry has become a well-deserved textile power, and the industry is showing strong vigor and vitality in the process of the great rejuvenation of the Chinese nation.

The pressures in the development of China’s textile industry

The future is bright, but the road never runs smooth. Since 2019, affected by such factors as trade disputes and geopolitics, the growth of the world economy has slowed significantly, and international demand has been sluggish. The IMF lowered the global economic growth four times during the year. The World Economic Outlook, released in October, lowered the global economic growth rate to 3.0% in 2019. Facing the severe external environment and the pressure of real transformation, the development of the industry is in a difficult period.

Production maintained a low growth rate. According to the National Bureau of Statistics, from January to October, the industrial added value of textile enterprises above designated size increased by 2.4% year on year, which was a slowdown of 0.6 percentage point from the same period of last year. In all links of the industrial chain, except for the chemical fiber industry and the filament weaving industry, where the added value maintained a relatively rapid growth, the rest of the growth slowed down. The added value of the chemical fiber industry from January to October increased by 11.5% year on year, a growth rate of 3.3 percentage points higher than the same period of the previous year; the added value of the filament weaving industry increased by 16.2% year on year, which was 9.2 percentage points higher than the same period of the previous year.

End products are under great pressure. From January to October, the added value of industrial and apparel industries increased by 7.2% and 1.0% respectively year on year, and the growth rates slowed down by 1.2 and 3.8 percentage points from the same period of the previous year, respectively. The added value of the home textile industry even showed negative growth. From January to October, it decreased by 1.0% year on year, and decreased by 5.3 percentage points compared with the same period of the previous year. The growth rate of the added value of the textile machinery industry continued to decline, with a year-on-year decrease of 6.0% from January to October, and the growth rate slowed sharply by 17.4 percentage points compared with the same period of last year. With increasing downward pressure, the space for corporate transformation and upgrading has been squeezed to a certain extent, especially for SMEs.

Domestic sales growth has slowed down. According to data from the National Bureau of Statistics, from January to October, the retail sales of clothing, shoes, hats, knitwear and textile above the national limit was 1062.4 billion RMB, a year-on-year increase of 2.8%, and the growth rate was slower by 5.6 percentage points compared with the same period of the previous year, which was 4.9 percentage points lower than that of the total retail sales of consumer goods. Online retailing still maintains a good growth momentum, but since June there have been signs of slowing down month by month. From January to October, the retail sales of online clothing products nationwide increased by 7.1% year on year, and the growth rates slowed down by 15.4 and 14.3 percentage points from the same period of the previous year and the first half of this year, respectively. The domestic consumption potential needs to be further tapped, and the development of traditional retail and online integration need to be upgraded.

The export market is under pressure. Affected by the weakening of the international economic recovery and changes in the trading environment, export pressure in 2019 increased significantly compared with the same period of the previous year, and the adjustment of product structure and market structure accelerated. From January to October, China’s textile and apparel export value was 232.31 billion USD, a year-on-year decrease of 2.2%. From the perspective of product structure, from January to October, the value of textile exports increased by 0.8% year on year, while the value of apparel exports fell by 4.5% year on year. In terms of export markets, the scale of exports to developed countries has declined, while exports to emerging markets have been more active. From January to October, China’s exports of textiles and apparel to the United States, the European Union, and Japan witnessed respective year-on-year decreased by 4.5%, 5.0%, and 5.5%; the total exports to the countries and regions along the “Belt and Road” increased by 1.3%; and exports to Africa increased by 6.6% year on year. With the normalization of trade frictions, active structural adjustment is a must for the companies.

The industry suffered sluggish investment. Since 2019, affected by insufficient domestic and foreign demand, the textile industry’s willingness to invest has been sluggish, and the decline in investment growth has gradually been severer since June. According to data from the National Bureau of Statistics, from January to October, China textile industry ’s investment in fixed assets fell by 7.0% year on year. Among them, the fixed assets investment in textile industry decreased by 8.5% year on year, a year-on-year decrease of 0.5% in apparel industry, and a year-on-year decrease of 18.6% in chemical fiber manufacturing industry.

In terms of different regions, 5 provinces and cities including Tianjin showed a good trend of positive investment in the entire industrial chain. Guangdong and Shandong provinces saw rapid declines in fixed asset investment in apparel industry. The textile and chemical fiber industries in Xinjiang Uygur Autonomous Region suffered respectively year-on-year decreases by 45.5% and 52.3% affected by industrial policy adjustments.

The economic operation has fluctuated slightly. Since 2019, the profit pressure of textile companies has increased, and it has become more difficult to improve the quality of operations. According to data from the National Bureau of Statistics, from January to October, the operating income of 34,000 textile enterprises above designated size in the country achieved 4,027.104 billion RMB, a year-on-year increase of 0.2%, which was a slowdown of 3 percentage points from the first half of this year. The total profit reached 168.81 billion RMB, down 8.7% year on year and 4.7 percentage points lower than that in the first half of this year. From January to September, the operating profit margin of textile enterprises above designated size was 4.2%, which was 0.4 percentage point lower than the same period of the previous year, and the profitability of the enterprise decreased compared with the same period of the previous year. The cost pressure of enterprises is relatively large, and the operation fluctuation needs to be taken seriously.

In general, under the complex situation of significantly increased risk challenges at home and abroad, the downward pressure on the textile industry has increased since 2019, but the industry still plays an active role in steady growth and stable expectations.

Part 3 The new situation and changes facing the current industry development

At present, the world is experiencing changes that have not occurred in a century, and technological advances have accelerated the progress of the industry. The core capabilities of different countries, regions, and enterprises are rapidly updated, and future development is highly complex. We need to follow the trend and grasp the times.

Seize the key adjustment period of the world industrial structure and find a good positioning. The power contrast is adjusting. Emerging market countries and regions are rising collectively. This is particularly evident in Asia. Asia’s share of global GDP in 2017 has reached 36.5%, exceeding North America and Europe; in 2018, the world’s regional R & D investment accounted for 40%. Asia has become the most active region in the global economic development, and the world’s textile and apparel industry is mainly distributed in this region. In 2018, the top ten countries in global staple fiber and yarn production accounted for 84% and 87% of the world’s total output, of which Asian countries and regions accounted for 66.1% and 82.1% of the top ten countries; the top ten countries and regions in textiles and clothing exports accounted for 86.2% and 83.3% of the world’s total, of which the Asian countries and regions accounted for 68.46% and 65.75% of the top ten countries, respectively. The prosperity of the region has enriched a large number of high-quality resources, creating conditions for the sustainable development of the entire industry. The rise of economies such as Vietnam, India, and Bangladesh have also changed the pattern of division of labor and trade. China’s textile industry needs to speed up adjustments to its product structure, capacity structure, and trade structure to better integrate into regional development.

Organizational structure is being adjusted. Global value chains have become an important form of international division of labor. More than two-thirds of world trade is generated through global value chains. The formation of global value chains has profoundly explained the trend of “connected manufacturing”. The deep development of the value chain has made the global division of labor more detailed, and cooperation has become a trend. The economic systems of different countries have generally evolved towards a more specialized direction, and it has become increasingly difficult to form large and comprehensive industrial systems. China has a complete industrial system, and its pivotal role in traditional trade and global value chain connection has become increasingly prominent. The refinement of division of labor has also continuously enriched the content of trade. Many products and services that were not traded before have been commercialized. According to World Bank data, 65% of trade categories in 2017 did not exist in 1992. Technology is a key factor in the value chain. The technical characteristics of the product determine the governance structure of the value chain and the distribution of benefits to the participants. Currently, the United States and Germany remain the most important hubs in the global value chain connection. In order for China to improve its position in the global value chain, it must continuously strengthen technological innovation.

Trade rules are being adjusted. Rapid development of global regional and bilateral trade agreements. There are currently 696 regional free trade agreements on record in the WTO, of which 481 have already entered into force. The regionalization of trade has profoundly affected the industrial structure. On the one hand, the simplification and unification of rules has promoted the flow of resources in the region and reduced transaction costs and risks. On the other hand, the content agreement of regional agreements is easier to reach and fuller. For example, the digital economy and intellectual property rights are usually among them, which paves the way for future regional industry cooperation. For example, the RCEP to be reached early next year will strengthen regional industrial cooperation, change the cost structure, and reshape the supply chain relationship. We should pay great attention to this.

The development mode is being adjusted. The concept of sustainable development has become an international consensus and has accelerated its implementation, which has affected the global industrial pattern extensively and deeply. This effect is achieved through three mechanisms. The first is the policy mechanism. Globally, the number of environmental protection policies and regulations has grown exponentially, requiring stricter and higher requirements, and deepening the content. Although some emerging economies started late, they have higher environmental protection requirements. The second is the market mechanism. Sustainable development is becoming a key factor affecting market decisions. More and more international buyers are beginning to select partners based on sustainable requirements. This year, Nike introduced the “The Future of Cycle-guided Design” workbook, which requires suppliers to adhere to 10 sustainable development practices. The Boston Consulting Group survey shows that 75% of consumers consider product sustainability to be important. The third is the financial mechanism. Sustainability has become an important indicator for the capital market to measure systemic risks and evaluate corporate development. From the establishment of the Principles for Responsible Investment (PRI) to April 2018, the size of assets managed by signatories has increased from USD 6.5 trillion to USD 81.7 trillion. Green finance is booming. Under the influence of these forces, the company’s green technology innovation, process innovation, and model innovation are becoming increasingly active. The global industry chain structure is more cyclical, balanced and coordinated. Some links with higher pollution and higher environmental protection costs are undergoing upgrading or replacement.

Seize the important window period of the fourth industrial revolution and speed up the assault

The fourth industrial revolution is reshaping the world’s industrial ecology and profoundly changing the global production and lifestyle, innovation and development paradigms. In this wave, technological innovation is becoming the core variable to reshape the industrial landscape.

The fourth industrial revolution presents three major technological trends.

The first is intelligence. Information technology is the underlying architecture of the fourth industrial revolution. The world economy is accelerating to build on the information infrastructure, many of which have the power to change the entire industry chain. For example, blockchain technology with distributed accounting, asymmetric encryption, and peer-to-peer transmission as its content can achieve data tamper-resistance, full traceability, and great potential in solving trust issues. The integration of industrialization and informatization is promising. Dayang Trands’ smart clothing customization factory can complete all categories of suits and women’s clothing. The production cycle is as short as four days and the daily output is close to 20,000 sets. Technological development also brings new risks to information security in the industry. Data shows that more than 90% of logins to global e-commerce sites come from hackers. We must make good use of new technologies and guard against new risks.

The second is integration. From micro to macro, from physics to information, from chemistry to biology, cross-fusion of technology is an important feature of this industrial revolution. The convergence of technologies drives the convergence of industries. Concentrated performance is the emergence of a large number of cross-border formats such as intelligent manufacturing and new retail. The disappearance of industrial boundaries has promoted the enrichment of product functions. Major projects such as large aircraft and Shenzhou spacecraft are the result of technological integration. As far as the industry is concerned, the top ten textile innovation products selected by China National Textile and Apparel Council have also fully reflected the trend of technological integration. Such as single-lead intelligent electrocardiographic clothing of Aide Intelligent Technology Co., Ltd., graphene smart heating down jacket jointly developed by Septwolves & Aika Technology. The integration of technology makes technological innovation a “complex system”. In order to achieve breakthroughs in innovation in a single individual and a single field, capacity has been stretched. Only multi-party collaboration and open cooperation are the way out.

The third is green. Compared with the past, the development of technology for social good and green is one of the most distinctive characteristics of this industrial revolution. According to statistics, the global green technology industry market share exceeded 3 trillion euros in 2016, and by 2025, this number will reach 5 trillion euros. Green technology is profoundly changing the development model. In the energy sector, the share of renewable energy in the global energy structure is increasing. Over the past 10 years, renewable energy has grown at an average rate of 5.4% per year. In the field of materials, the greening of materials throughout the life cycle is advancing. For example, corn, chitin, and other biomass are used to replace petroleum to prepare “green fibers” and “bio-based materials.” In the manufacturing field, clean production and green manufacturing are developing rapidly, intelligent manufacturing is widely used, and the production process is shifting to low entropy. The digital dyeing and printing factory built by Huafang Co. Ltd. is a good example. Technologies such as waste sorting and separation and pretreatment continue to advance, and circular economy is accelerating, such as Ningbo Dafa Chemical Fiber’s “integrated technology for efficient recycling of waste polyester and industrialization of fiber preparation.”

Manufacturing is the art and science of making raw materials into new products to meet new demands. The textile and apparel industry is a development aesthetics that integrates production, ecology, and life. Intelligent manufacturing, connected manufacturing, custom manufacturing, and green manufacturing will be the core of the future industrial revolution. The transformation of production methods will determine whether it can occupy the commanding heights of future development.

Correctly treating the fourth industrial revolution

The fourth industrial revolution has given the industry the opportunity to restructure its comparative advantages and achieve “asymmetric” catch-up. We must speed up the layout and move faster; but at the same time, we must avoid the tendency of generalization and deification.

The fourth industrial revolution cannot be simply understood as the information revolution. Information technology is an important component of this technological revolution. Combining the “Top Ten Breakthrough Technologies in the World” released by MIT from 2001 to 2019, it can be found that the number of information technologies accounts for 50% of the total. However, the development of information technology is only the foundation and precursor of the industrial revolution. The broader space of the digital economy is not the industrialization of information but the informationization of the industry. The structural changes of the world’s top ten breakthrough technologies over the years can well illustrate this point. Eight of the top ten breakthrough technologies in 2001 were information technology. By 2019, there will be only three information technologies, and the rest are industrial application technologies. The “New Vision of the Global Digital Economy” also shows that in 2018, the industrial digitization of the countries it follows accounted for more than 50% of the digital economy, and the scale of China’s industrial digitization reached 24.9 trillion yuan, about four times the scale of digital industrialization. The greater space for the new industrial revolution lies in the industry, and it should not fall into the illusion of “de-manufacturing.”

Individual technologies in the fourth industrial revolution cannot be regarded as a “panacea” that solves all problems. At present, the fourth industrial revolution is still in its infancy. Many technical applications are immature. Throughout history, the application of new technologies has never been immediate, but has to withstand a long-term test of economic and social development. The instability of the new technology makes the initial investment large and the cost of trial and error high. At the same time, in the process of industrialization of new technologies, it is necessary to get rid of the path dependence of the original mainstream technologies, which has a large conversion cost. Too aggressive technology strategies often carry significant risks. For example, Adidas will close its speed-factory in Germany and the United States, and transfer its capacity to Asia. For the industrial application of emerging technologies such as quantum computing, we must take a positive, prudent, rational and pragmatic attitude.

The technological divide in the fourth industrial revolution is widening, and if it does not keep up, it will be locked in the lower end of the innovation chain. WIPO statistics show that the top five countries in the world in terms of total patent applications increased from 76.9% in 1994 to 77.5% in 2018. Driven by global value chain cooperation, technology tends to be standardized and modular. Encapsulated technology products make many low-tech countries simply call, but cannot go deep into the bottom of technology. On the other hand, the integration and complexity of technology in the new industrial revolution means that scientific and technological innovation requires diversified and deep accumulation in the early stage, high-quality infrastructure support, and high-level technological investment. At the same time, rapid changes in technology mean high trial and error costs. This is often unbearable for countries with weak economic strength. The technological innovation of the Chinese textile industry has accumulated certain innovation advantages in several cutting-edge technological fields and has the basic conditions for leading international technological innovation. We must firmly grasp the time window of the fourth industrial revolution and accelerate the upgrading of the value chain and innovation chain.

Seize the period of strategic opportunity for the great rejuvenation of the Chinese nation and take active actions

A high-quality national governance system and governance capacity are being formed. After years of exploration, especially since the 18th National Congress of the Communist Party of China, China’s system has been continuously improved, the state governance system and governance capacity have been accelerated towards modernization, and the institutional advantages of socialism with Chinese characteristics have been brought into full play. The Fourth Plenary Session of the 19th CPC Central Committee will raise the governance system and governance capacity to a new height, providing a fundamental basis for China’s comprehensive deepening reform in the new period. With the continuous improvement of governance capabilities, the boundaries between government management, social management, and market coordination will become clearer, and functions will be more coordinated and scientific. The state is continuously creating a competitive market environment to support the development of the private and real economies; it is continuing to deepen market-oriented reforms and remove institutional barriers that hinder the free flow of factors, and market vitality will be further stimulated. With the continuous progress of the rule of law in China, there will be fewer and fewer special services and more inclusive benefits. The management activities and business activities of enterprises will be more rule-based. And the gray areas of the new economy will gradually disappear. Enterprises need to adjust their business models in a timely manner to adapt to a more legal and clear market environment.

A high-quality economic system is taking shape. The construction of a modern economic system is an important support for the realization of the Chinese dream of the great rejuvenation of the Chinese nation. The modernization of the economic system is accelerating. The industrial system continues to upgrade. China is the only country in the world with all industrial categories in the United Nations industrial classification. The huge industrial ecology has provided a huge stage for innovation and development. Data from the Fourth National Economic Census shows that the industrial structure is being optimized, and the number of high-tech manufacturing legal entities in the manufacturing industry above designated size has reached 9.5%. The innovation system is constantly improved. China places innovation and development at the core of the country’s overall development. In 2018, China’s R & D expenditures were 1,965.7 billion yuan, a year-on-year increase of 11.6%; R & D expenditures exceeded 2% for five consecutive years, ranking the top among developing countries. The development of information technology facilities and innovation systems has accelerated. These have created excellent conditions for the industry to enhance its core capabilities. Regional systems are more coordinated. The state continuously optimizes the spatial layout through policy and strategic guidance, promotes the rational flow and efficient concentration of resource elements, and accelerates the construction of a high-quality development power system. Regional industry support is constantly improving. On December 1, the CPC Central Committee and the State Council issued the “Outline of the Yangtze River Delta Regional Integration Development Plan.” The outline clearly stated that “the nation’s advanced manufacturing agglomeration area” should be established, and in the future, a number of national strategic emerging industrial bases will be built around ten major fields such as electronic information, new materials, green chemicals, textiles and clothing, and a number of world-class manufacturing industries clusters will be formed. Industry development is ushering in new opportunities.

A high-quality domestic demand market is emerging. In the process of the great rejuvenation of the Chinese nation, the quality of life, income level and consumption capacity of the Chinese people have been continuously improved. Consumption has become the primary driver of economic growth for five consecutive years. In the first three quarters of 2019, the final consumption expenditure contributed 60.5% to economic growth. China has formed the largest middle-income group in the world. Consumption upgrading has become a trend, and demand has shown characteristics of personalization, diversification, and quality. An important manifestation is the continuous strengthening of cultural self-confidence in consumption. For example, the rise of Hanfu, according to estimates, has more than 2 million consumers in the Hanfu market across the country, with a total industry size of about 1.09 billion yuan. With the continuous deepening of urbanization, regional coordinated development, and targeted poverty alleviation, the potential of sinking markets is also being released. At the same time, the cultivation of Chinese consumers’ online habits has been completed. An interesting phenomenon is that even if the online price of some products is higher than offline, consumers still ignore this reverse price difference due to path dependence. From November 1st to 11th this year, China’s online retail sales exceeded 870 billion yuan, a year-on-year increase of 26.7%. Consumption upgrades, the rise of sinking markets, and the maturity of the Internet market are shaping the market opportunities for industry development in the new era.

A high-quality open pattern is taking shape. Opening up to the outside world is the only way to realize the great rejuvenation of the Chinese nation. The World Bank’s “Doing Business 2020” report shows that China’s business environment ranking has accelerated from 78th in 2017 to 31st in 2019, and has been ranked among the top ten economies with the largest improvement in business environment in the world for the second consecutive year. In the new era, China is forming a new pattern of opening up in an all-round, multi-level and wide-ranging field. This year, a series of policies such as “Special Administrative Measures (Negative List) for the Access of Foreign Investment (2019)” and “Industrial Catalog for Encouraging Foreign Investment (2019)” were issued, which strongly promoted the in-depth opening of finance, infrastructure, culture, manufacturing and other fields. According to data from the Ministry of Commerce, from January to October 2019, 33,407 new foreign-invested enterprises were established nationwide, a year-on-year decrease of 32.6%; the actual use of foreign capital was 752.41 billion yuan, a year-on-year increase of 6.6% (equivalent to USD 110.78 billion, a year-on-year increase of 2.9%). China actively promotes the conclusion of regional agreements such as RCEP, China-Japan-Korea Free Trade Area, and promotes win-win regional cooperation. The quality of “going global” is getting higher and higher. Cross-border mergers and acquisitions, capacity transfer, and technical cooperation have effectively broadened the space for industrial development. The deepening of the opening up pattern provides opportunities for the industry to make good use of both international and domestic markets and resources.

Part 4 The main work planned by China National Textile and Apparel Council in the next stage

In general, although the internal and external environment we are facing is becoming more and more complex, the development of the industry is in a period of important strategic opportunities. To achieve high-quality development, we need to do the right things at the right time, find the right focus and balance, and grasp the rhythm and strength.

Strengthen the vision and tell the true story of the textile industry

Strategic positioning determines the value ceiling. People’s recognition of an industry’s vision is profoundly affecting the resources and future development space that the industry can integrate. Take the global fintech financing in 2018 as an example, the artificial intelligence field with an application rate of only 8%, and the venture capital obtained in 2018 has surged by 72%. After years of development, the connotation of China’s textile industry has taken a qualitative leap. High-quality high-performance fiber industry, intelligent high-end textile manufacturing industry, fashion industry driven by brand and creative design, and industrial textile industry deeply integrated into major projects of national economy and people’s livelihood are all organic components of the industry. However, domestic society’s cognition of the industry is relatively lagging behind. Some experts and media put labels such as backward production capacity and sunset industry on the industry, and there is a big gap between the industry’s development achievements and social evaluation.

This gap has seriously affected the industry’s attractiveness to key resources such as talent, capital, and policies. It is difficult to recruit workers, finance, and obtain government support. To resolve prejudice requires the joint efforts of our entire industry. Correct the prejudice with active practice, increase the industrial voice, and break the “silent spiral.” To this end, in 2020, China National Textile and Apparel Council will organize research on the guidance for the development of the “14th Five-Year Plan” industry, compile the “14th Five-Year Plan” for the scientific and technological progress of the textile industry, and prepare and release the “14th Five-Year Plan” for the industrial textile industry development guidance and other documents. Further improve the industry planning and guide the development of the industry, so that the new positioning of the industry of “science and technology, fashion, and green” will accelerate the formation of new industry practices and new social cognition.

Innovation and leadership, consolidating the basic capabilities of the textile industry

In the face of rapid changes in the environment, companies can only achieve sustainable development if they remain highly sensitive to new developments in technology, models, markets, and policies, and continuously improve their basic capabilities. China National Textile and Apparel Council will continue to be committed to service industry innovation.

The first is to do a good job of researching and judging the situation. Adhere to the problem-oriented approach, and make in-depth industry research, statistical analysis, and industry research. Pay close attention to key hot issues in the chemical fiber “microplastics”, the development of the cotton spinning industry in Xinjiang, and the layout of the central and western regions of the weaving industry, and carry out research on the “14th Five-Year Plan” under the background of the normalization of Sino-US trade frictions and economic transition. Promote related results to form problems, solutions, and services.

The second is to promote technological innovation. Strengthen the service capability of independent innovation of the industry, and consolidate basic research and applied basic research. Focusing on core technologies independently and controllable, it promotes the development and application of new fiber and key technologies and equipment for intelligent manufacturing. Accelerate the construction of the industry innovation system and promote the transformation of scientific and technological achievements in the industry. Strengthen the protection of intellectual property rights in the industry and strengthen the construction of standard systems. Continue to advance global scientific and technological cooperation.

The third is to promote fashion innovation. Focus on building cultural self-confidence, and accelerate the formation of a fashion ecology with Chinese characteristics, world influence, and era characteristics. Promote industrial development with industrial culture and contemporary fashion innovation based on Chinese excellent culture. “Master, big brand, big event” as the starting point to promote brand building. In the protection and inheritance, we will promote the branding and marketization of textile intangible cultural heritage.

The fourth is to promote sustainable development. Deepen the construction of industry social responsibility, and accelerate the promotion of green development standardization and the construction of corporate ecological civilization. Based on corporate social responsibility reports and regional social responsibility reports, pilot subdivided industries such as cellulose fiber industry social responsibility reports. Guide enterprises to eliminate backward production capacity, develop cleaner production, and build a green manufacturing system. Promote the application and transformation of key green technologies; develop the circular economy of the industry and promote the construction of green standards systems.

Balance the domestic and foreign markets and open up the development space of the textile industry

To achieve higher quality development, it is necessary to balance the international and domestic markets and consider how to coordinate resources on a larger scale and from a longer period. We must pay full attention to the economic, social, and ecological impact of the transfer industry, balance the rhythm and intensity of local development, regional transfer, and international industrial transfer to prevent hollowing out of the industry. Promoting the coordinated layout and development of industrial regions is an important task in the future.

The first is to stimulate effective demand and help the formation of a strong domestic market. Accelerate market cultivation, follow the trend of domestic consumption upgrade, guide the layout of the sinking market, and expand final demand. Promote the transformation of old and new kinetic energy in the industry and stabilize industry investment. Adjust the structure of the exhibition, accelerate the segmentation of the exhibition market, and create an entire industry chain and international brand exhibitions. Open up the Greater Bay Area market and the exhibition market in the central and western regions.

The second is to scientifically guide the industry to go global and build a new pattern of comprehensive opening up. Do basic research well and guide the industry to transfer scientifically and orderly. Completed “Research on Major Issues of “Going Global “in the Textile and Apparel Industry in the New Situation”, “Analysis of Internationalization Development and Trade Situation of the Textile Industry”, and tracked research on Sino-US economic and trade frictions. Deepen foreign exchanges and cooperation. Organize “Belt and Road” investment inspections and host the 2020 “Textile and Apparel Industry Dialogue under Lancang-Mekong Cooperation” annual conference. Continue to do well in mature markets in Europe and the United States, increase investment in developing countries such as Southeast Asia, and explore Central and Eastern European markets.

Intensive development, integrating the strong strength of the textile industry

China’s textile industry has the largest volume in the world, but the industrial concentration still needs to be improved. The decentralized industrial structure has caused the problem of homogeneous development from enterprises to clusters; there are many micro-innovations and weak strategic and fundamental innovation capabilities. In order for the industry to establish global comparative advantages with higher quality and efficiency, it is necessary to explore a new “national system” that integrates social resources and powers the entire industry, and fully combine the three advantages of focusing on major events, super large-scale industry, market and the decisive role of market in resource allocation. China National Textile and Apparel Council will actively promote the intensive development of the industry.

Develop a platform economy. Guide the construction of various platforms for enterprises, regions and industries, and give full play to the platform’s role of resource aggregation and integration. Promote the release of trends throughout the industry chain, product development collaboration and supply chain social responsibility management. Enrich and improve existing mechanisms for various types of industry technology innovation alliances, product innovation alliances, green development alliances, and collaborative innovation consortia. Improve the construction of public service platforms and promote the integration and development of large, medium-sized and small enterprises.

Develop industrial clusters. China National Textile and Apparel Council will continue to promote the construction of a world-class advanced textile and apparel industry cluster. Do a good job of tracking and research services in the pilot zone, give full play to the demonstration effect and leading effect of these regions; meet the requirements of “building a national advanced manufacturing concentration zone” in “the Outline of Regional Integrated Development of the Yangtze River Delta”, and promote the construction of national textile and garment strategic new industrial base and world-class advanced textile and apparel industry clusters. Guide and assist industrial clusters and industrial parks to make the “14th Five-Year Plan” and mid-to-long-term development strategies; guide industrial clusters, industrial parks, and professional markets for intelligent transformation and brand development. Explore and cultivate emerging industry clusters that are contemporary, forward-looking, and leading.

Promote integrated development. Deepen the integration of industrialization and informatization, promote the digital transformation of enterprises in organizational management, manufacturing, business models, etc.; promote the construction of industrial Internet platforms in the industry; and promote the construction of big data centers in the industry. Deepen the cooperation between the industry and the finance, continue to implement the “Three-year Action Plan for the Integration of Industry and Finance in the Textile Industry”, encourage and guide mergers, acquisitions and alliances between enterprises, and improve industry concentration and efficiency. The construction of a textile power is in progress. Let us work together to promote the excellence of China’s textile industry. Let innovation-driven technology industries, culture-led fashion industries, and responsibility-oriented green industries become the new normal for China’s textile and apparel industry.